MMBE series high shear emulsifier

-

INTRO

-

SUBTYPE

-

DETAIL

-

RELATED

Product overview:

The high-speed moving rotor and the precision-fitted stator produce centrifugal action, and the liquid is drawn into the stator cavity from the lower or upper part. The extruded liquid produces a strong jet, undergoes strong mechanical shearing, hydraulic shearing, and forms a cyclic shear, thereby mixing, dispersing, refining, dissolving, homogenizing, and emulsifying the material.

1、产品概述

The high-speed moving rotor and the precision-fitted stator produce centrifugal action, and the liquid is drawn into the stator cavity from the lower or upper part. The extruded liquid produces a strong jet, undergoes strong mechanical shearing, hydraulic shearing, and forms a cyclic shear, thereby mixing, dispersing, refining, dissolving, homogenizing, and emulsifying the material.

2、应用行业

3、产品特征

4、产品种类

catalog

-

1

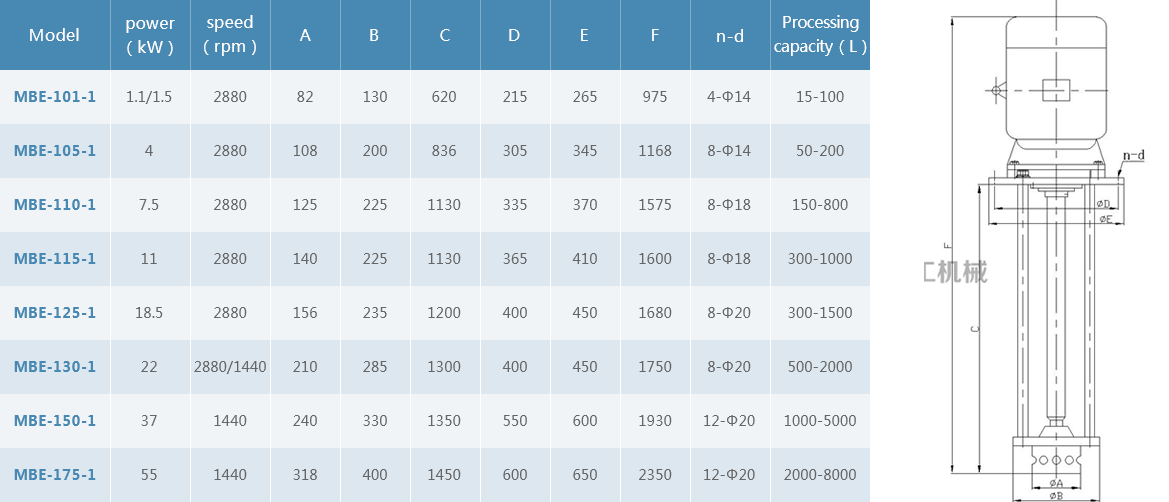

MBE-100 series high shear mixing emulsifier

-

2

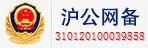

MBE-500 series high shear mixing emulsifier

-

3

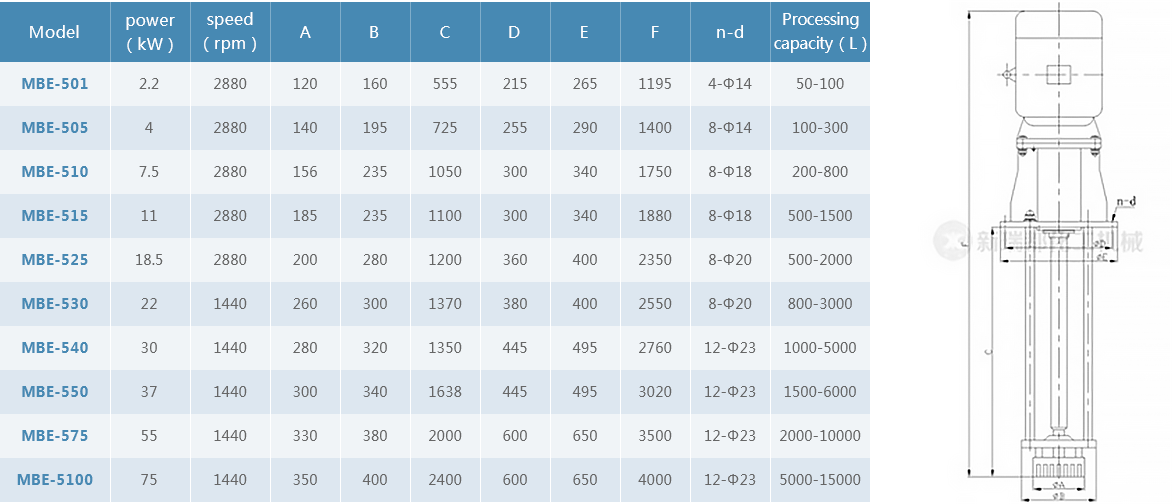

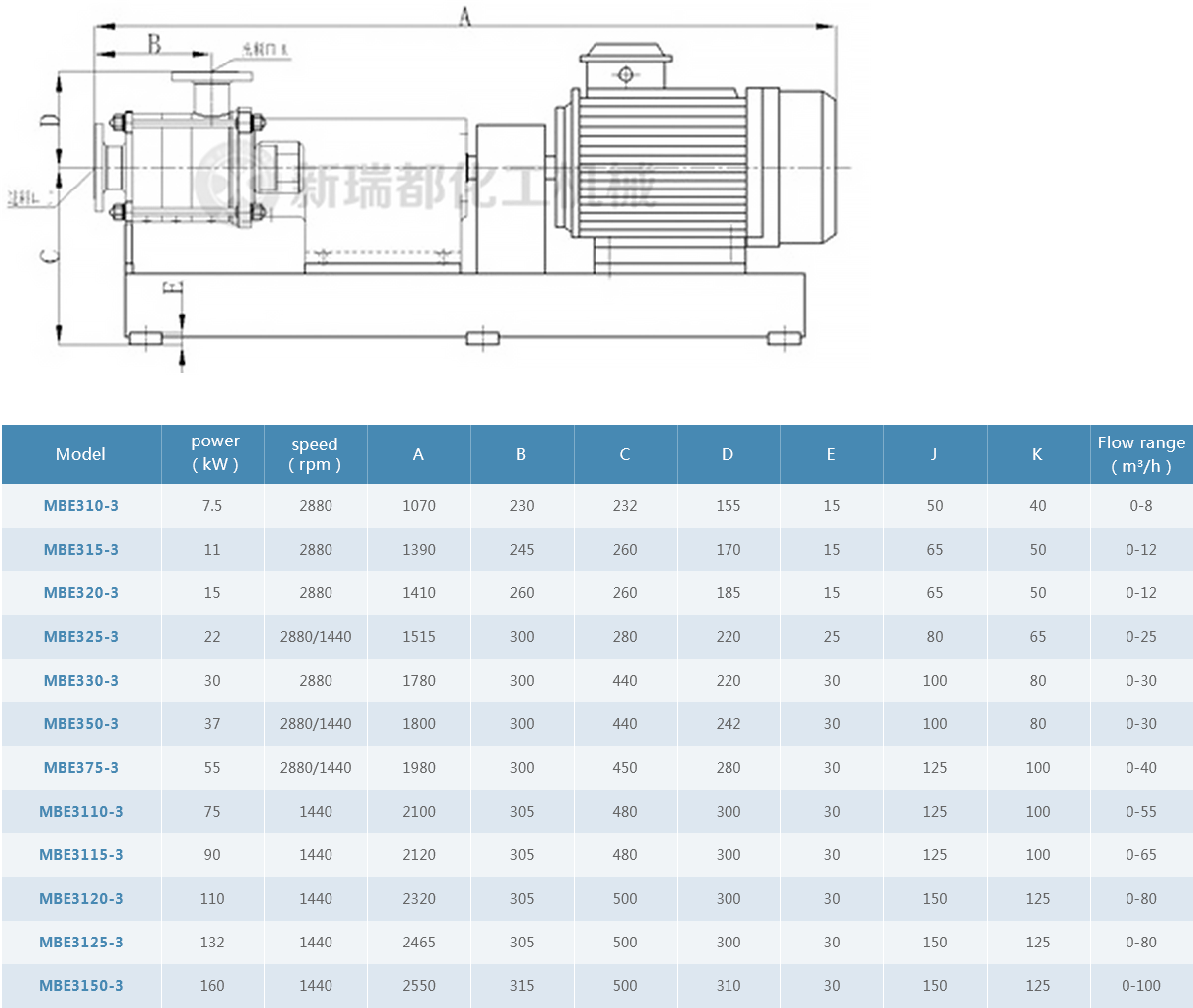

MBE-300 series pipeline emulsifier

-

Applicable to: Emulsification reactor, vacuum kettle, pressurized reactor, and heating kettle. NSK, SKF bearings are installed in the machine cavity, combined with mechanical seals, designed according to working conditions.

Technical parameter table (specifically designed according to container size)

Note:

1. The flow in the table is the data measured when the medium is “water”, and the flow rate of the materials will vary.

2. The material has poor fluidity. It is recommended to feed the corresponding pump at the inlet. The pumping pressure is P≤0.2Mpa

3. The number is subject to change without prior notice. The actual product shall prevail.

Applicable to: Industrial pipeline continuous production, cycle operations and remote automatic control.

Rotor design: design and manufacture from single stage---II level---III level duality

MBE300-1 type technical parameters

Note:

1. The flow in the table is the data measured when the medium is “water”, and the flow rate of the materials will vary.

2. If the material has poor fluidity, it is recommended to feed the corresponding pump at the inlet. The pumping pressure is P≤0.2Mpa

3. The parameters in the table are subject to change without prior notice. The actual product shall prevail.

4. If a recycling process is used, it is recommended to use it in combination with a batch high shear dispersing emulsifier.

5. If there are high temperature, high pressure, flammable, explosive, corrosive and other working conditions, it is necessary to clearly provide relevant and accurate parameters for further selection and formulation.

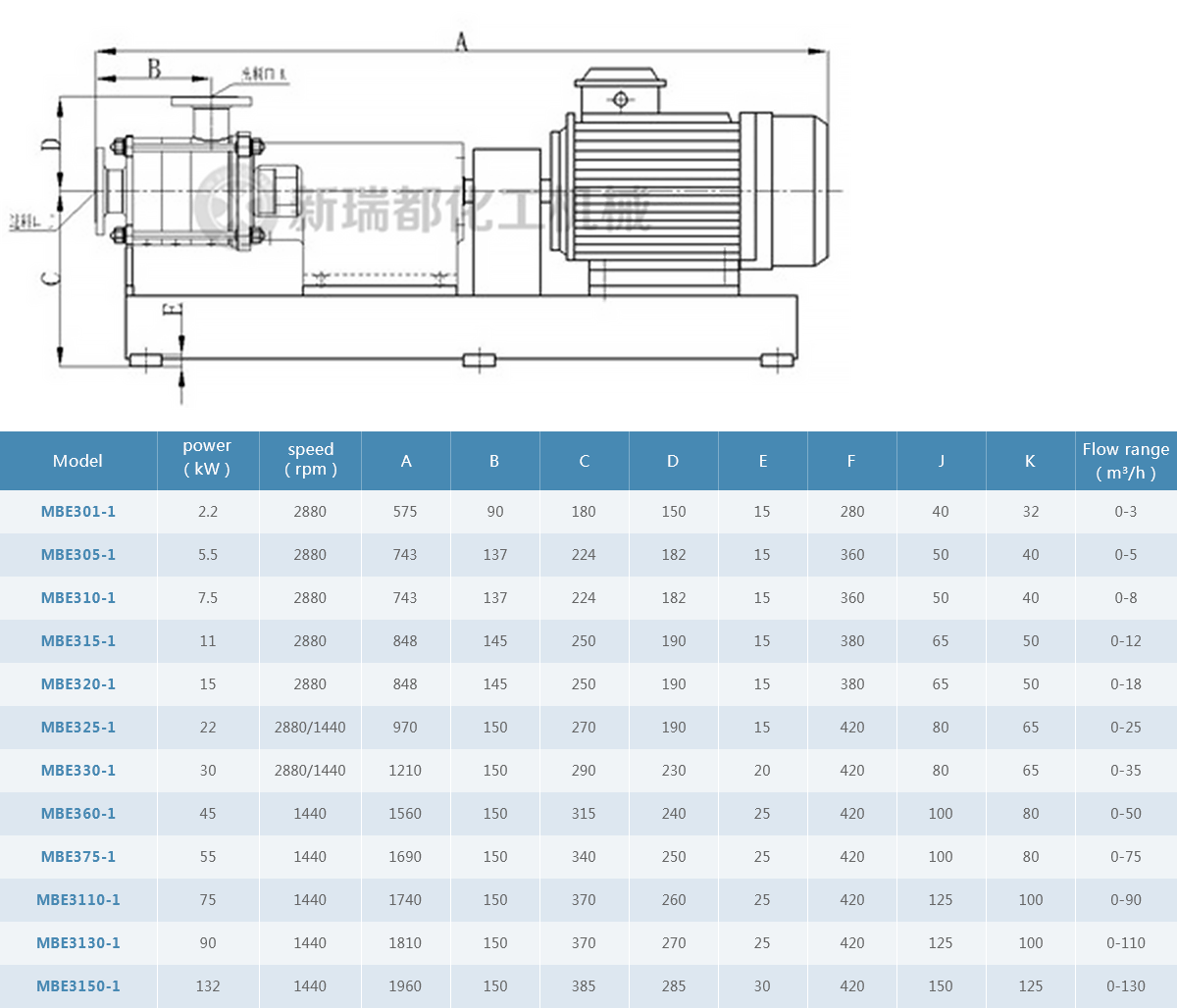

MBE300-II technical parameters

Note:

1. The flow in the table is the data measured when the medium is “water”, and the flow rate of the materials will vary.

2. If the material has poor fluidity, it is recommended to feed the corresponding pump at the inlet. The pumping pressure is P≤0.2Mpa

3. The parameters in the table are subject to change without prior notice. The actual product shall prevail.

4. If a recycling process is used, it is recommended to use it in combination with a batch high shear dispersing emulsifier.

5. If there are high temperature, high pressure, flammable, explosive, corrosive and other working conditions, it is necessary to clearly provide relevant and accurate parameters for further selection and formulation.

MBE-300III technical parameters

Note:

1. The flow in the table is the data measured when the medium is “water”, and the flow rate of the materials will vary.

2. If the material has poor fluidity, it is recommended to feed the corresponding pump at the inlet. The pumping pressure is P≤0.2Mpa

3. The parameters in the table are subject to change without prior notice. The actual product shall prevail.

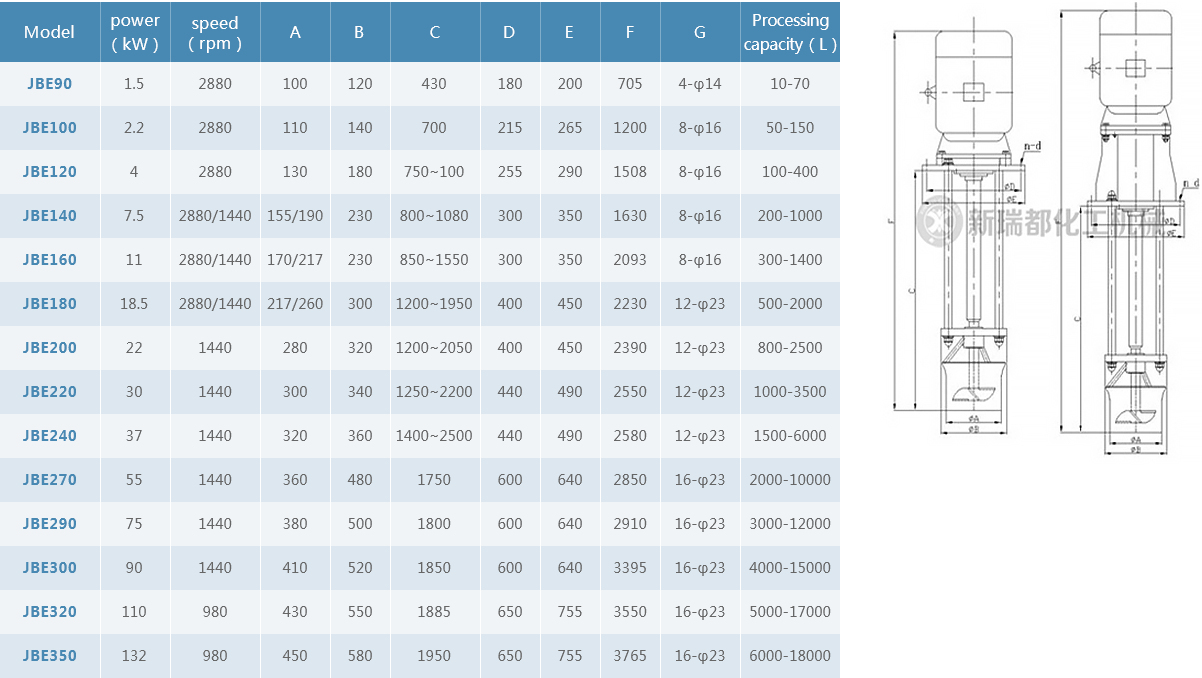

- Applicable to: Mixing, dispersing, dissolving, refining, homogenizing and emulsifying materials with high, medium and low viscosity. It is especially effective for liquid materials with large difference in specific gravity for suspended lightweight materials.

JBE (mechanical seal) technical parameters

JBE (normal pressure type) technical parameters

Address: Shanghai Fengxian Industrial Zone No. 99 car line

Address: Shanghai Fengxian Industrial Zone No. 99 car line

Fax: 021-64544111

Fax: 021-64544111

Email: xinruidu@xinruidu.com

Email: xinruidu@xinruidu.com

Tel:021-54488893 17701693701

Tel:021-54488893 17701693701

Sales Phone: 021-54488893 13901897168 17317632837

Sales Phone: 021-54488893 13901897168 17317632837

After sales call: 021-64544111 18930406998

After sales call: 021-64544111 18930406998